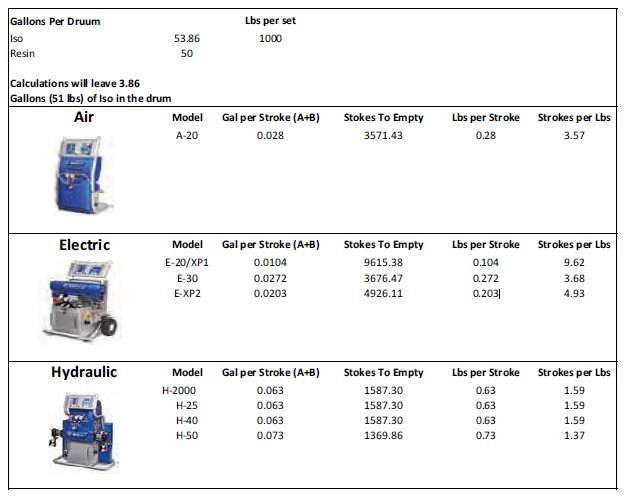

The chart above gives you the ideal numbers you should be aiming for. In order to get close to these numbers, your drums should be maintained at a 70-75 degree temp. They should stay at this temperature from the time they are opened to the time they are pumped dry. Achieving these numbers with your machine is the first thing needed to do, in order to get the most out of your product. For all foam machines, the pumps do not care what temperatures of the material is, just that they get "X" amount of fluid into them, on each stroke. Like everything in this world, when something cools off... it shrinks, and as it warms up... it expands. It's because of this scientific fact that you can get different cycle counts per set. The warmer your material is in the drum (and going into the machine), the more strokes you will get out of it. Remember that most 2 pound systems will start to have their blowing agents boil out of the material at 80-85 degrees. Every percentage of blowing agent you loose, a percentage of your yield is lost!

1 Comment

Leave a Reply. |

Author:

|

RSS Feed

RSS Feed